Features / Gas plant on budget and on schedule

THE £3.3 billion project to pipe the first West of Shetland gas through the islands to the UK is on budget and just three weeks behind schedule.

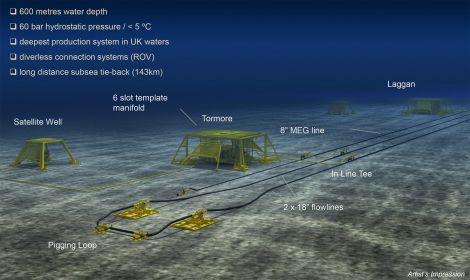

Gas from the Laggan-Tormore fields will start flowing next summer building up to full production of 500 million cubic feet per day by the end of 2014.

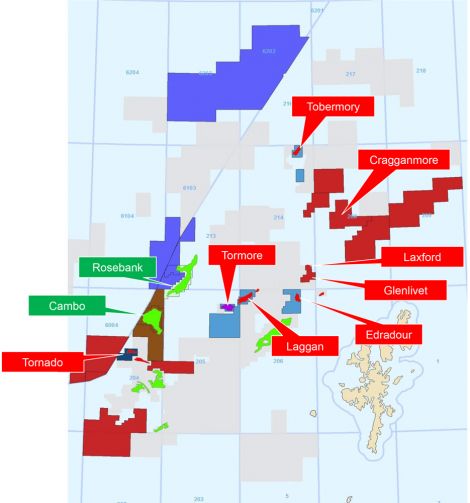

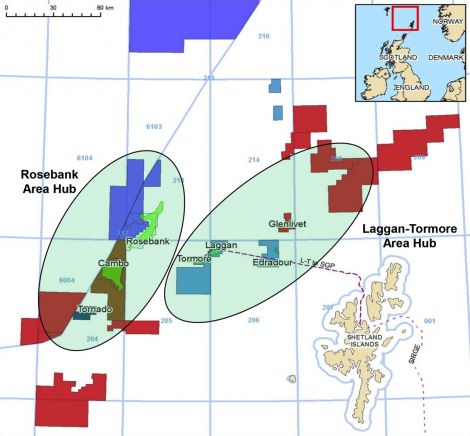

Gas from Chevron’s Rosebank field further west will bypass Shetland to be piped directly to Scotland, while oil from the field may be shipped direct to mainland refineries denying business for Sullom Voe oil terminal.

Two 143 kilometre flowlines bringing Laggan-Tormore gas into the £800 million onshore gas plant being built by French energy giant Total will unlock around one fifth of Britain’s remaining hydrocarbon resources.

By tying in several neighbouring fields currently being appraised and developed, it promises to keep the gas plant operating beyond the 30 years originally forecast.

As Total and its partners DONG Energy, the Danish state-owned oil and gas business, enter the final leg of their massive construction project the workforce on site is ramping up to its peak of 1,400 employees.

A third accommodation barge, Sans Vitesse, is due in Lerwick harbour this month to house the last 100 workers to join the squad putting together modules that are being shipped in from east Asia, the Middle East, Europe and the US.

Shetland’s economy is forecast to receive almost £200 million over the lifetime of the Laggan-Tormore project, including a payment to Shetland Islands Council based on throughput, details of which remain confidential.

However more income is in the pipeline as new fields come on stream in the next few years.

DONG are the company with the widest involvement in the West of Shetland region, with a 20 per cent stake in Laggan-Tormore and a finger in the pie of all the other fields being developed in the north Atlantic.

Become a supporter of Shetland News

The company, which only began operating in the UK 12 years ago, is the world’s biggest builder and operator of offshore wind farms, and is involved with coal, oil, gas and electricity distribution around the world.

The largest offshore oil and gas developer off Denmark, it is the seventh largest off Norway. The UK now accounts for 27 per cent of the company’s business, and this figure is likely to grow.

A triumvirate of senior DONG directors were in Shetland this week to promote their involvement in unlocking the huge gas reserves lying in deep water west of here.

Brent Cheshire was the company’s only employee when they opened a UK office in 2004, now he is chairman of an operation with 400 staff in this country.

In that time DONG, which stands for Danish Oil and Natural Gas – “an unfortunate name” – has invested £5.5 billion in the UK and plans to build itself into a major player in the new era of deepwater exploration and production.

West of Shetland they also have a stake with Total in Edradour, Glenlivet and Cragganmore, all of which will hopefully tie into the Laggan-Tormore pipeline, along with other neighbouring gas fields.

They are also hoping to open up a new hub with Chevron at the Rosebank oil and gas field, where oil will be extracted using an FPSO which could well bypass Sullom Voe and be shipped straight to refineries.

The gas from the field is being tied into the 234 kilometre SIRGE line taking gas from Shetland to the FUKA line and on to the St Fergus processing plant in Aberdeenshire, and will not go through the Shetland gas plant.

Nearby Tornado and Combo could tie in to Rosebank bringing oil and gas ashore from the border with Faroese waters.

“On average this area is as big as the central and the northern North Sea, it is a very exciting area to be working in,” Cheshire said.

“It’s not an easy place to work, and Laggan-Tormore at 600 metres is the deepest development in the UK so far and is in a very harsh environment.

“But we do believe we have a mousetrap that works here and we have participated in most of the discoveries that have been made.”

The harsh conditions make it a very expensive place to work and though Tormore was discovered in 1986, it was not viable to develop it until 2007 when Laggan was found 16 kilometres away.

Cheshire chaired the UK task force set up at the insistence of the UK government to extract the maximum value from the west of Shetland.

He said that initially all the major players, including BP, Shell and Exxon, were involved but by the end it was just Total and DONG who committed to the hub that would crack open the region to bring its buried treasure ashore.

Many of the fields are still being assessed to see if they can be commercially produced, but confidence is so high that more gas will come ashore in Shetland that room has been made for extra pipelines to be laid along Yell Sound.

DONG is committed to developing hydrocarbons in northern Europe with fields in Scandinavia, the UK and Greenland.

It also has an eye on transitioning to a low carbon future – 55 per cent of its offshore generating business is wind power, with 45 per cent made up of oil and gas.

The company is trying to divest itself from its coal-fired power stations in Denmark, converting them to biomass, and sees gas as an ideal bridge to renewables.

In 2007 they produced 33,000 barrels of oil equivalent per day, which has almost tripled to 86,200 today, with a target of 150,000 by 2020.

Exploration director Søren Gath Hansen said having “cracked the code” west of Shetland, they see a lot of new opportunities in the long term.

“We believe the world needs green energy, but we recognise this is not something you do from one day to another and we see gas as a good clean future fuel,” he said.

Development and operations director Simon Slater explained they had now entered the final leg of the huge project, which he described as “a global jigsaw puzzle” that always had Shetland at its core.

He said local firms were already benefitting hugely and the partnership was committed to being a good neighbour, involving itself in the community, protecting the environment and supporting the economy.

They are particularly proud of their two peat stores which contain 280 swimming pools worth of peat that took a year to settle and is steadily monitored to ensure its stays healthy until it is used decades hence to reinstate the site.

They also boast of their £1 million scheme to train 15 local apprentices as oil and gas technicians who will eventually be part of the 80 strong team running the gas plant.

Slater said the £185 million benefit to the local economy included payments to Shetland Islands Council based on throughput as well as rent and rates, but did not include money that would come from future gas projects, the first of which will be Edradour followed by Glenlivet.

DONG is the minor player in the partnership, and regards itself as “a second pair of eyes” for Total to consult.

Cheshire said it was the best partnership he had ever experienced in his long history in the industry and they worked extremely well together.

Total’s tough project director for West of Shetland, Robert Faulds, said Laggan-Tormore and the gas plant were just three weeks behind schedule, dismissing persistent rumours that it has slipped by as much as 18 months.

“Three weeks is nothing on a project this size, a couple of months would be quite normal,” he said.

There has been a steady turnover of around five or six workers each week, many being asked to leave as a result of the company’s zero tolerance to unsafe or antisocial behaviour.

As for the industrial dispute over sharing bedrooms at the 848 bed accommodation block at Sella Ness, which threatened to trigger a walk out during the summer, Faulds said there was still some work to do.

Some share, some don’t, but they get no extra cash for sharing, he said, adding that there was a job there for those that wanted it, but if they didn’t they could leave.

Become a supporter of Shetland News

Shetland News is asking its many readers to consider start paying for their dose of the latest local news delivered straight to their PC, tablet or mobile phone.

Journalism comes at a price and because that price is not being paid in today’s rapidly changing media world, most publishers - national and local - struggle financially despite very healthy audience figures.

Most online publishers have started charging for access to their websites, others have chosen a different route. Shetland News currently has over 600 supporters who are all making small voluntary financial contributions. All funds go towards covering our cost and improving the service further.

Your contribution will ensure Shetland News can: -

- Bring you the headlines as they happen;

- Stay editorially independent;

- Give a voice to the community;

- Grow site traffic further;

- Research and publish more in-depth news, including more Shetland Lives features.

If you appreciate what we do and feel strongly about impartial local journalism, then please become a supporter of Shetland News by either making a single payment or monthly subscription.

Support us from as little as £3 per month – it only takes a minute to sign up. Thank you.